Evolutionizing the clothing industry with human-centric deep tech

Scan, capture and leverage actual 3D body data of real consumers to define and match sizes and sewing patterns – making made-to-measure scalable.

Deep Tech

As seen in

Our value proposition

Digitizing the clothing industry

We aim to reconnect consumers with the clothing industry to meet both their needs while connecting the physical with the digital world.

Leveraging body measurement data

Enabling the clothing industry to use their customers‘ body data independently to learn how they are sized and shaped.

Providing virtual try-ons and fit-checks

We provide the clothing industry with virtual visual try-on solutions to let customers perform instant fit-checks through their devices.

Optimizing production cycles

Our solutions support an agile production process that enables a sustainable future-proof clothing production system.

Our Core

Our core

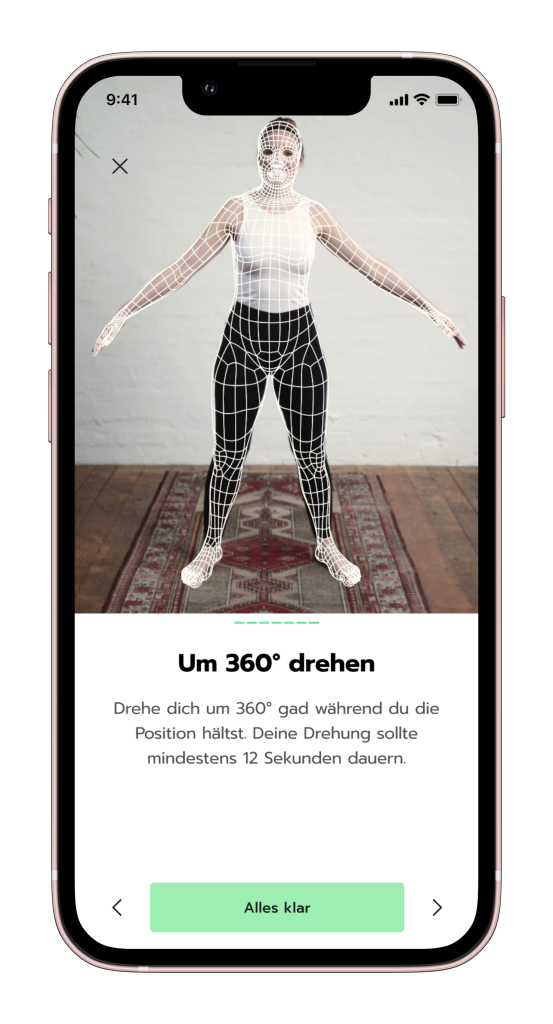

Using deep tech

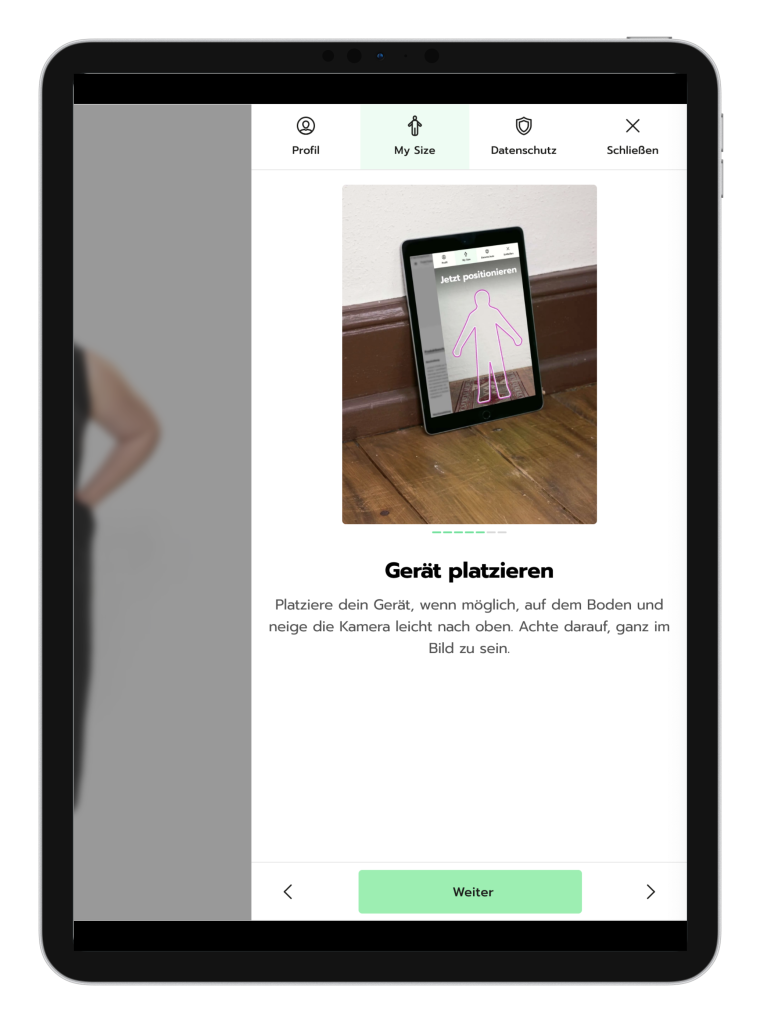

Our patented 3D body scanning solution for mobile devices capture the most complete and accurate set of body measurements, generating a 3D avatar that exactly describes the proportions, shape, and measurements of individual bodies.

With over 90K scans in our database we are able to deliver valuable analytics, statistics and insights and recommendations based on ai-powered algorithms and deep tech.

Our proprietary IT approach combines 3D, 4D, AI and classic data bank architecture and aligns it with expertise in apparel manufacturing.

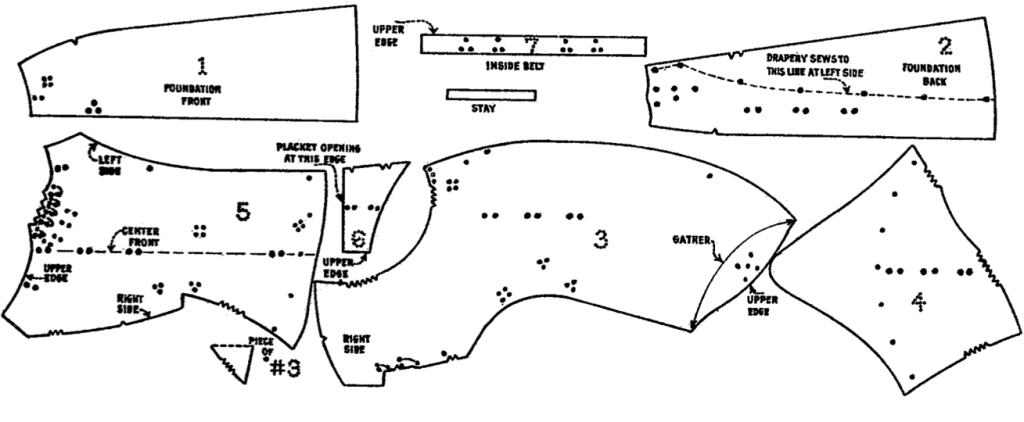

We hold a patent for 3D/4D based pattern development.

Our reason – the root of the problem

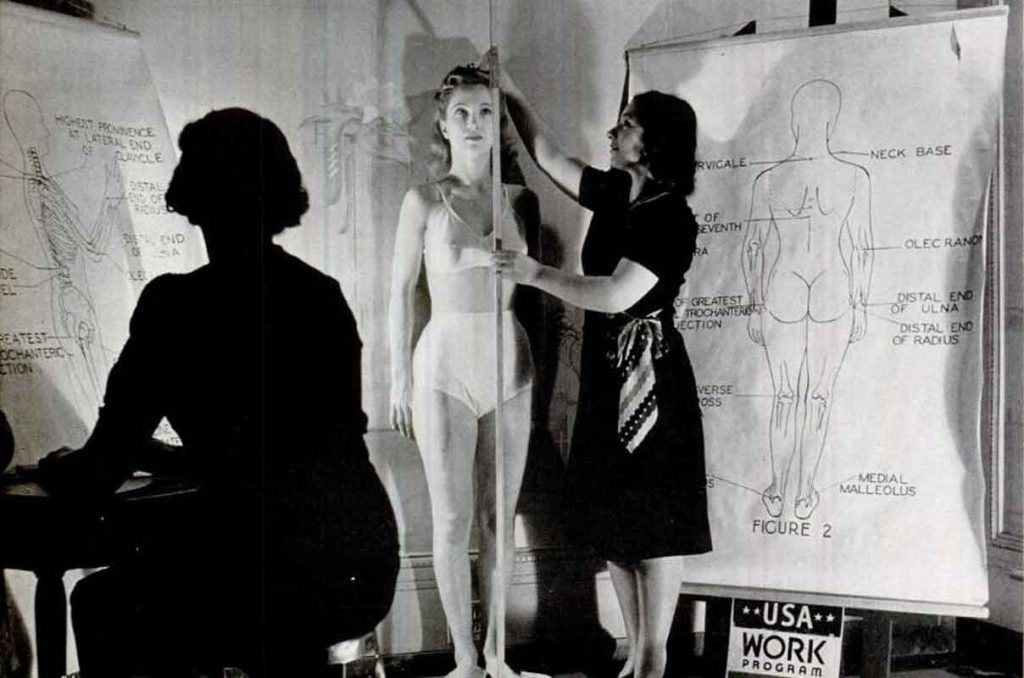

The clothing technology hasn't evolved during the past 160 years.

The history

Bespoke tailoring

First Industrial Revolution

In 1863 E. Butterick developed sewing patterns for mass production principles.

Made-to-measure clothing. Two collections per year.

Second Industrial (Technological) Revolution

Standardization of size charts, standardized sizes and statistical mean.

Third Industrial (Digital) Revolution

Mass production principles and centralized factory production. 50-100 micro collections per year.

Industry 4.0

Now is the time for change with digital data sets, avatar systems, digital production, made-to-measure and local micro factories.

Standard sizes were made to serve fast fashion consumerism and led to mediocre-fitting clothes.

Since E. Butterick developed sewing patterns for mass production principles in 1863 nothing much has developed on how measurements are taken and transcribed into standardized sewing patterns and sizing charts that are used worldwide.

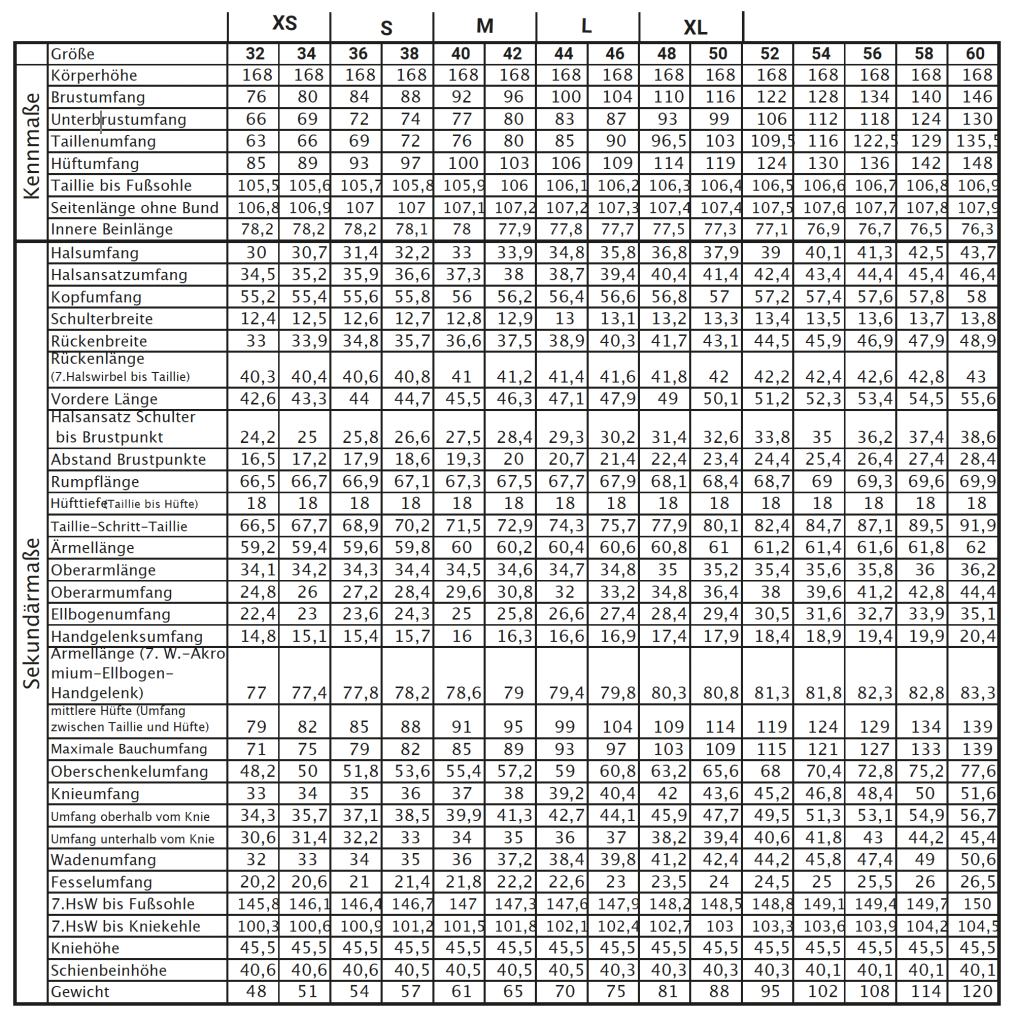

Standardized size charts were last updated in 1970 for men and 1990 for women and are compiled from the averages of the population at that time. They are based on 2D manual measured data points and fail to take the diverse distribution of body proportions into consideration.

The fashion industry is making clothes for calculated averages but people with standard measurements don’t exist.

Our why

The consequences

Today’s mass production of standard-sized, so-so-fitting clothes results in consumer frustration, high return rates, overproduction, waste of time and resources, textile waste and pollution.

Consumers

Only 30% of the population fits into standard clothing sizes.

Clothing industry

Over 50% of online returns are due to size fitting problems which leads to billions of returns globally and 40% overproduction.

Our world

The textile industry is the 2nd biggest polluter in the world. 30% of unsold items get thrown away.

Consumers

Only 30% of the population fits into standard clothing sizes.

Clothing industry

Over 50% of online returns are due to size fitting problems which leads to billions of returns globally and 40% overproduction.

Our world

The textile industry is the 2nd biggest polluter in the world. 30% of unsold items get thrown away.

New EU norm and regulations for sustainable production and consumption in fashion

To reduce the burden for our environment, the EU just released a strategy for sustainable and circular textiles to make sustainable products the norm which tackles fast fashion, textile waste and the destruction of unsold textiles; and to ensure the production respects human rights.

Our solutions

Our solutions create a symbiotic customer-business-relationship and benefit the consumers, the clothing industry and the environment alike.

Our solutions

Our solutions create a symbiotic customer-business-relationship and benefit the consumers, the clothing industry and the environment alike.

For consumers (humans 😉)

BEAWEAR app

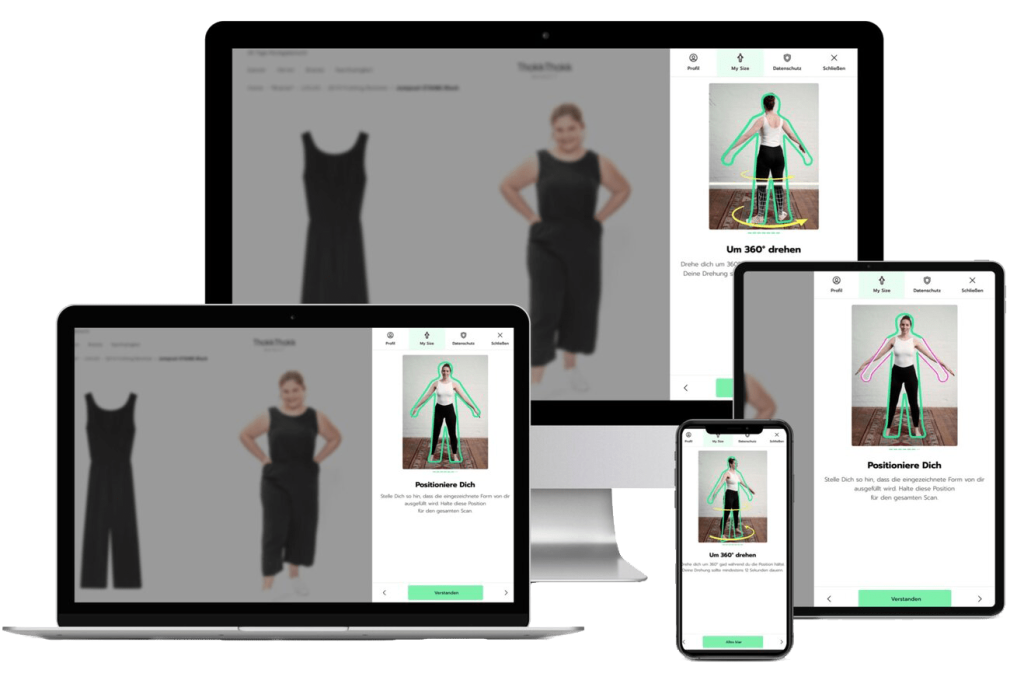

Customers can easily scan themselves and get exact size recommendations based on their personal body data to make informed buying decisions.

They own their data and can use their avatar for virtual try-ons on all connected platforms while simultaneously enjoying a gamified and VR-enhanced “phygital” shopping experience.

For e-commerce

API solution

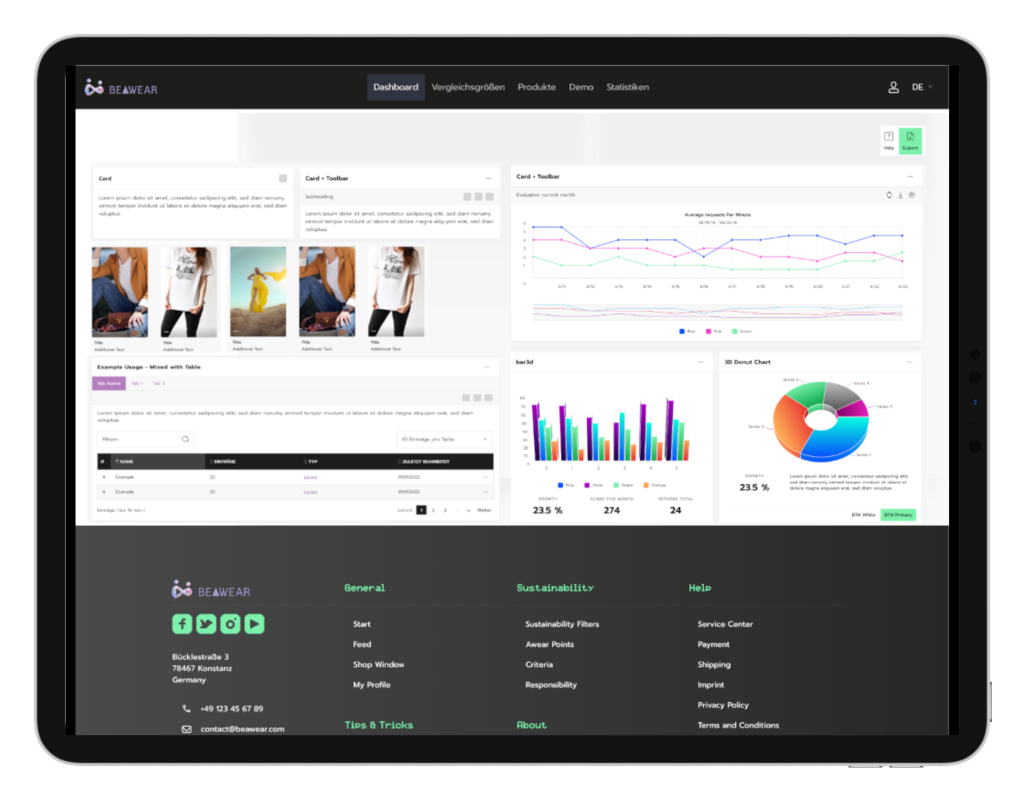

Our plug-and-play API allows shop owners to implement our 3D body scan solution with accurate size recommendations, virtual try-ons as well as extensive consumer data analytics in a separate admin dashboard.

- More available data on customer body sizes, morphotypes and size matches

- Increased controlling quality e.g. for orders and production

- Increased accuracy of size charts and sewing patterns

- Less returns

- CO2 emission savings

We offer packages for all types of brands, producers and retailers in the fashion industry as well as specific solutions for the workwear industry.

To learn more about our API plugins and packages

For clothing producers

Sewing patterns and size charts

Our recommendations based on real body data allow producers to adjust their sewing patterns and size charts according to their customers bodies.

- Increase data communication with ecommerce

- Produce better fitting clothes

- Less time to market

- Production on demand

- Minimize overproduction

The overall results

Our solutions create a symbiotic customer-business-relationship and benefit the consumers, the clothing industry and the environment alike.

- better fitting clothes for everyone

- happier customers

- fewer returns

- optimized value chain

- saved costs due to demand-oriented production and more accurate inventory

- better sell-through

- less time to market

- less waste and pollution

- reduced climate and biodiversity impact

The movement

Be part of the change!

Everybody who scans themselves takes part in improving size recommendation, size chart accuracy and sewing pattern development based on real human bodies to achieve more inclusive and better fitting clothes and thus protect the environment.

Join the movement and support our mission for clothes that fit and scan your body now!